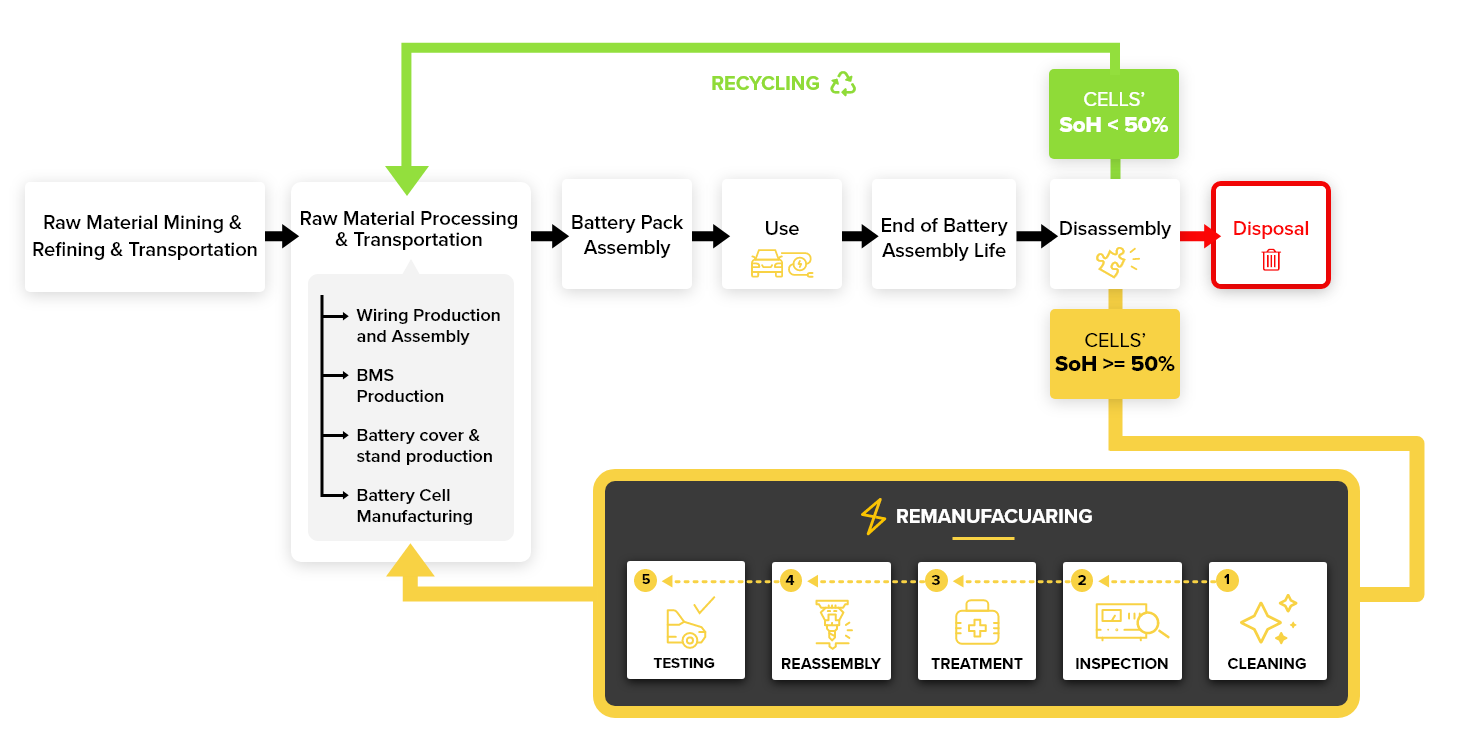

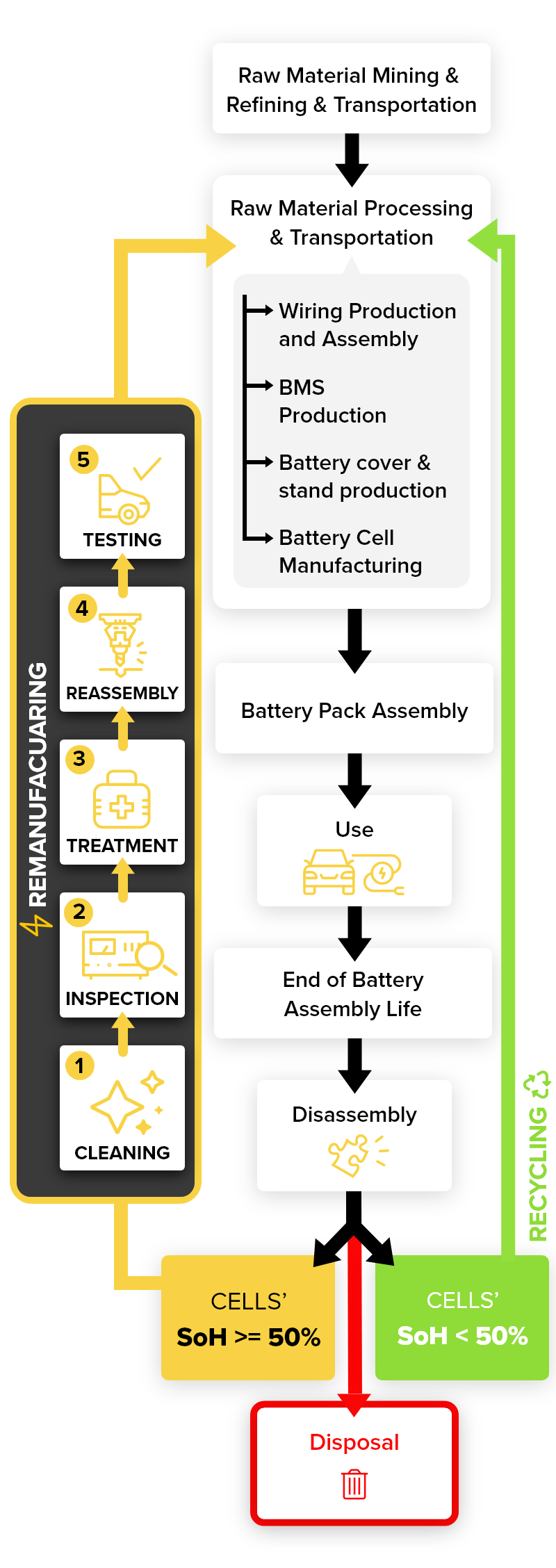

HYBRID Battery Manufacturing & Re-Manufacturing flow chart

All HYBRID and Electric Vehicle (EV) battery re-manufacturing is not made equal. Because this is still an unregulated industry, there are a lot of steps involved in doing it correctly and those steps cover a few vital areas:

STEP 1.

- Battery Pack (BP) disassembling

- Recording Initial voltage of each Cell

- Separating the Cells

- Cleaning each Cell with proper cleaning Agent

- Assembling the Cells

STEP 2.

- Recording the Internal Resistance (IR) of each Cell

- Starting the Discharge and Charge sequence

- Recording the Discharge and Charge values

- Identifying Unusable Cell(s)

- Replacing Unusable Cells with Healthy Ones

- Discharge and Charge to determine the health of the Cells

- Cell Grouping

- Record the Grouping

- Balancing the Pack

At this point the Cell Pack is ready for final assembly

STEP 3.

- Cleaning the Fan

- Cleaning the Cover and inside the Battery Pack

- Cleaning and DE-rusting all Copper Contacts and Cell Nuts

- if necessary, replacing Copper Contacts and Cell Nuts with new ones

STEP 4.

- Assembling the Battery Pack

- Torquing all Nuts and Bolts to manufacturer’s recommended values

- Recording the Voltage and Capacity of the Pack

- Generating the Final Report

- Shrink Wrapping the Pack

At this point the Healthy Re-Manufactured Pack is ready for shipping